Step‑by‑Step Guide to Sourcing Injection Molding in China

So, the big meeting just wrapped up. your new product is a go, the schedule is tight, and funding is, to put it mildly, limited. Then someone—maybe your boss, maybe the finance director—utters the phrase that sends a little jolt down every project manager’s spine: “We should look at sourcing this from China.”

You nod, of course. On paper, it’s logical. The potential savings can be massive. However, your brain is racing with concerns. You’ve heard all the horror stories, right? The quality disasters, the communication black holes, the shipment that shows up three months late looking nothing like the sample. It’s like balancing on a tightrope between a massive cost advantage and project disaster.

But here’s the catch. Sourcing plastic mold can be a calculated project. It’s simply another project with clear steps. And as with any project, success depends on your methodology. It’s less about finding the absolute cheapest quote and more about finding the right partner and managing the process with your eyes wide open. Ignore the nightmare anecdotes. Let’s walk through a real-world playbook for getting it right.

Step One: Do Your Homework

Before you mention “supplier” or browse Alibaba, organize your internal data. Honestly, more than half of all overseas manufacturing problems start right here, with a weak or incomplete information package. You can’t expect a factory on the other side of the world to read your mind. A vague RFQ is like telling a contractor to bid on “a house.” You’ll get wildly varied quotes that are useless.

Aim to craft an RFQ package so precise and comprehensive it leaves no room for error. It’s the cornerstone of your entire effort.

What belongs in your RFQ?

Start with your 3D design files. They’re essential. Stick to universal formats like STEP or IGS to avoid any compatibility headaches. This is the master blueprint for your part’s geometry.

Yet 3D models don’t cover everything. You also need detailed 2D drawings. This is where you call out the stuff that a 3D model can’t communicate. I’m talking about critical tolerances (like ‘25.00±0.05 mm’), material specifications, required surface finishes, and notes on which features are absolutely critical to function. If a specific surface needs to be perfectly smooth for a seal, or a particular hole diameter is vital for an assembly, your 2D drawing needs to shout it from the rooftops.

Then specify the material. Avoid generic terms like “Plastic.” Don’t even just say “ABS.” Be specific. Call out SABIC Cycolac MG38 (black), for example. Why so detailed? Because resin grades number in the thousands. Specifying the exact resin grade ensures you get the strength, flexibility, UV resistance, and color consistency you planned for with what is plastic mold.

A good supplier can suggest alternatives, but you need to give them a clear starting point.

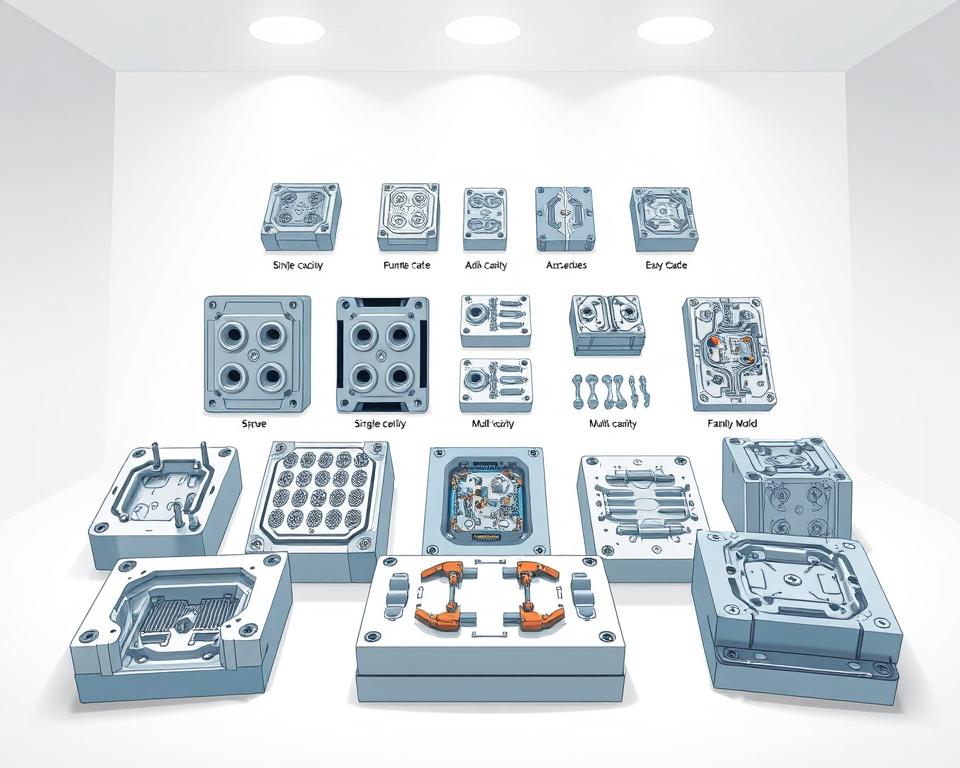

Don’t forget the commercial info. State your EAU. You must specify if it’s a 1K-part tool or a 1M-part production run. The tool design, the number of cavities, and the price per part all hinge on this number.

Hunting for the Best Supplier

With your RFQ perfected, now, who do you send it to? The web is vast but overwhelming. Locating vendors is easy; vetting them is the real challenge.

Your search will likely start on platforms like Alibaba or Made-in-China.com. They let you survey dozens of suppliers quickly. Use them to build a shortlist, not the final list. Aim for a preliminary list of 10–15 potential partners.

Still, you must dig deeper. Consider using a sourcing agent. True, they charge a fee. But a good one has a vetted network of factories they trust. They handle local liaison and oversight. As a newcomer, this offers priceless security. It’s schedule protection.

Another tactic: trade exhibitions. If you can attend, shows such as Chinaplas transform sourcing. Nothing beats a face-to-face conversation. You can handle sample parts, meet the engineers, and get a gut feeling for a company in a way that emails just can’t match. And don’t forget the oldest trick in the book: referrals. Consult trusted colleagues. A solid referral can be more valuable than any ad.

Shortlisting Serious Suppliers

With your RFQ dispatched to dozens of firms, estimates roll in. You’ll see ridiculously low offers and steep quotes. Your task is to filter them down to 2–3 credible finalists.

What’s the method? It involves both metrics and gut feel.

First, look at their communication. Do they respond quickly and clearly? Do they communicate effectively in English? The true litmus: are they raising smart queries? Top vendors will critique and inquire. Example: “Should we add draft here for better ejection?” or “Your tolerance may require extended CMM time—okay?” That’s a huge positive sign. It shows they’re engaged and experienced. A supplier who just says “No problem” to everything is a walking red flag.

Then confirm their machinery specs. Request their machine list. Review examples of parts akin to your design. A small-gear shop won’t cut it for a big housing.

Then comes the audit. You can’t skip this. Just as you interview hires, audit suppliers. Either visit in person or engage a local audit service. They dispatch an on-site auditor for a day. They authenticate the firm, review ISO credentials, evaluate machines, and survey operations. That small investment can save you thousands.

Converting Digital Designs into Molded Parts

You’ve selected your partner. you’ve negotiated the price and payment terms—a common structure is 50% of the tooling cost upfront to begin work, and the final 50% after you approve the first samples. Now the process kicks off.

The first thing you should get back after sending your payment is a DFM report. DFM stands for Design for Manufacturability. It’s their professional review of your CAD. It will highlight potential issues like areas with thick walls that could sink, sharp corners that could cause stress, or surfaces without enough draft angle for clean ejection from the mold. A thorough DFM is a sign of a professional operation. It’s a two-way partnership. You work with their engineers to refine the design for optimal production.

Once the DFM is approved, they’ll start cutting steel to make your injection mold tool. A few weeks later, you’ll get an email that will make your heart beat a little faster: “T1 samples have shipped.” These are the very first parts off the new tool. They are your moment of truth.

Expect T1s to need tweaks. This is normal! There will be tiny imperfections, a dimension that’s slightly out of spec, or a blemish on the surface. You supply feedback, they tweak the tool, and T2 plastic mold company samples follow. You may repeat this cycle a few times. The key for you, as the project manager, is to have this iteration loop built into your timeline from the start.

Finally, a flawless part arrives. Dimensions, finish, and performance all check out. This is now the benchmark sample. You formally approve it, and this sample is now the standard against which all future mass-produced parts will be judged.

Completing the Sourcing Journey

Receiving the golden sample seems like victory, but you’re not done. Now comes full-scale production. How can you keep part #10,000 matching your golden sample?

Put a strong QC process in place. Typically, this means a pre-shipment audit. Again, you can hire a third-party service. They’ll randomly select parts, compare them to specs and golden sample, and deliver a detailed report. You receive a full report with images and measurements. Once you sign off, you greenlight shipping and the last payment. This simple step prevents you from receiving a container full of scrap metal.

Lastly, plan logistics. Clarify your Incoterms. Is your price FOB (Free On Board), meaning the supplier’s responsibility ends when the goods are loaded onto the ship in China? Or EXW, where you handle everything from their gate? These details have a big impact on your final landed cost.

China sourcing is a long-haul effort. It relies on partnership-building. View them as allies, not vendors. Clear communication, mutual respect, and a solid process are your keys to success. No question, it’s demanding. But with this roadmap, you can succeed, achieve savings, and maintain quality. You’re set to succeed.